YiLi Custom Silk Grenadin Tie – Handmade Emerald Green with Floral Pattern

| CLASSIC NECKTIE | |||

|---|---|---|---|

| Age Group | Length (inches) | Blade (cm) | Tail (cm) |

| Aldult | 57~59 | 145~150 | |

| Youth | 61~63 | 150~160 | |

| Children's | 47~52 | 120 ~ 130 | |

| CLIP-ON TIE | ||

|---|---|---|

| Age Group | Length (inches) | Blade (cm) |

| Adult | 57~59 | 145~150 |

| Youth | 54 | 137 |

| Children's | 61~63 | 150~160 |

| ZIPPER TIE | ||

|---|---|---|

| Age Group | Length (inches) | Blade (cm) |

| Adult | 57~59 | 145~150 |

| Youth | 54 | 137 |

| Children's | 61~63 | 150~160 |

| SAFETY TIE | ||

|---|---|---|

| Age Group | Length (inches) | Blade (cm) |

| Adult | 57~59 | 145~150 |

| Youth | 54 | 137 |

| Children's | 61~63 | 150~160 |

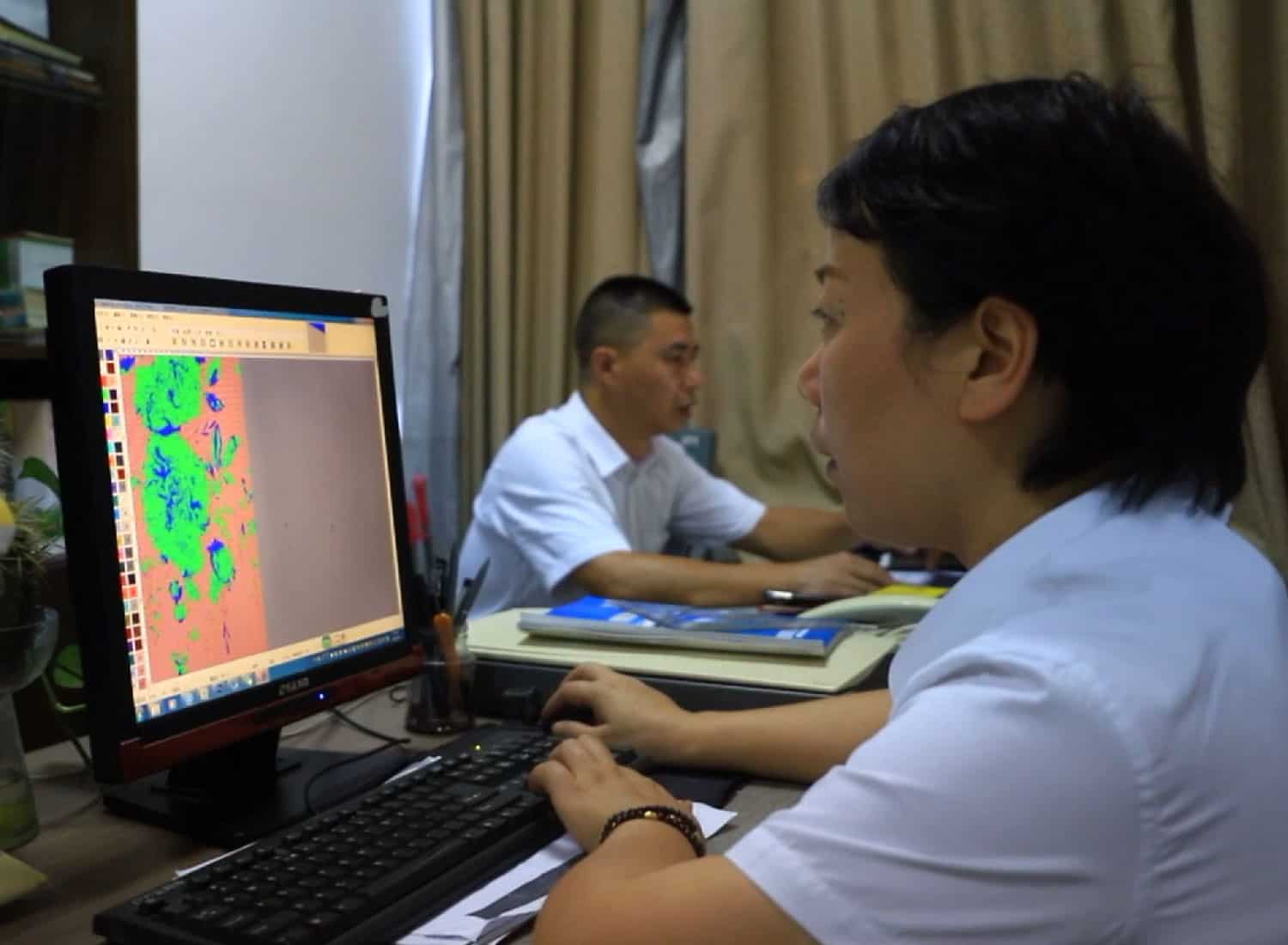

Meet Our Factory

Necktie Production Process

Designing

Fabric Weaving

Fabric Inspection

Fabric Cutting

Label Stiching

Finished Inspection

Needle Checking

Packing & Storage

Necktie Sewing

Liba Machine Sewing

Necktie Ironing

Hand Sewing

Estimated Project Cost

To ensure that your business will have enough profit, it is essential to determine the overall cost of your project before officially starting it. Here are some of the expenses that you can expect to incur during the project:

Design Fee

If you need us to customize your tie design, we charge a fee of USD 20 per style. You don't have to worry about your design being leaked. If you use our design, we don't charge any design fee.

Product Cost

It depends on the style, material, design, quantity, and other factors of your customized tie. Our ties offer a super low MOQ: 50 pcs/design, and you can test your project for very little money.

Transportation

CostsShipping costs depend on the quantity of ties your order and your region.

Tariff

Almost all countries will charge tariffs for imported products, and the charges differ in different countries. You can consult our sales representatives if you don't know how much your country will charge.

Sample fee

We can provide free samples if you want to check our product quality. You only pay for shipping. If you need customized samples, we will also charge a design fee.

Other costs

In some special cases, a special fee will be charged. If you ask a third party to inspect the goods. Or you need to enjoy government tariff relief, you need to provide a certificate of origin, etc.

If you want to start working in the tie industry, I suggest you check out our article - Is it a big investment to start a necktie business?

Estimated manufacturing and shipping times

Before starting a project, you will have a project schedule. Knowing how long the tie-making process will take will keep your plan on track. Below is the time it takes for our tie-making mass production.

Step 1 - Sample Production

Including tie design, fabric production, tie making, tie inspection, and other steps. With our excellent and complete team, we only need five days to complete the production of custom tie samples.

Step 2 - Sample Confirmation

Including international transportation, customer inspection, communication modification, etc.

This process mainly takes time for international transportation and customer confirmation, which takes about 10~15 days.

Step 3 - Mass Production

Including fabric production, tie production, inspection, and packaging.

The mass production time is between 18~22 days; the specific time is related to the quantity you ordered.

Step 4- International Shipping

Including customs declaration, international transportation, customs clearance, local distribution, etc.

Shipping time is related to the shipping method; by sea is about 30 days, and Express and Air freight are about 10~15 days.

Why Choose YiLi

YiLi Necktie & Garment is a company that values customer satisfaction from the hometown of neckties in the world-Shengzhou. We always aim to produce and deliver quality Neckties that meet all your needs.

Hot products

According our clients feedback

YiLi not only produces ties. We also customize bow ties, pocket squares, women's silk scarves, jacquard fabrics, and other products that customers love. Here are some of our products that customers love:

Novel product design constantly brings us new customers, but the key to retaining customers is product quality. From the beginning of fabric production to the completion of cost, we have 7 inspection processes:

2-300x300.jpg)