The necktie we know and love today has been around for more than 400 years. From the hand-painted neckties of post-WWI to the wild and wide neckties of the 1940s to the skinny ties of the late 1970s, the necktie has remained a constant staple of men's fashion. Yili necktie is a necktie manufacturer in Shengzhou, China. This article will detail the anatomical tie structure from the manufacturer's perspective to help buyers familiarize themselves with the system and details to help design the perfect tie.

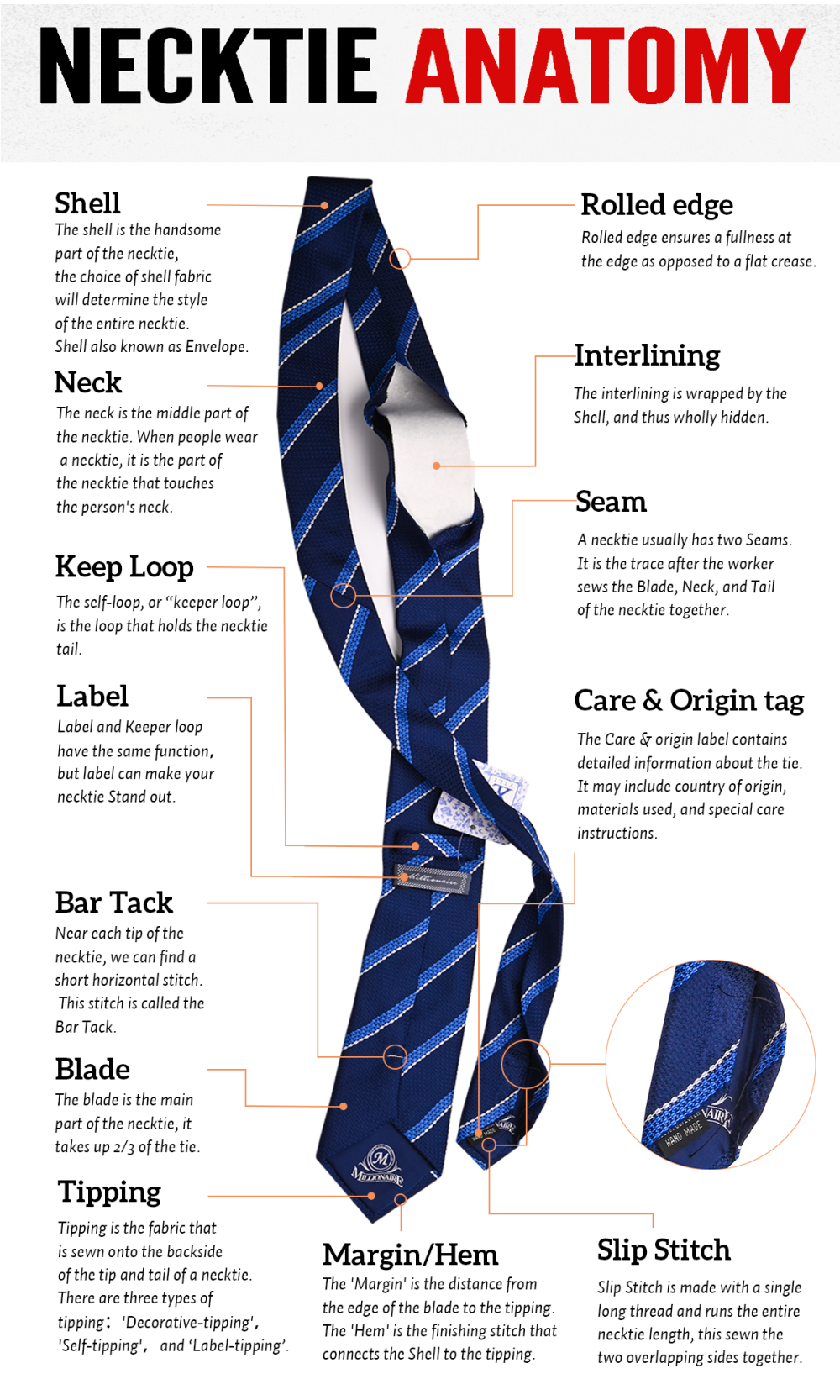

The complete Necktie Anatomy Chart

Primary structures of the Necktie

1. Shell

The shell is the handsome part of the necktie. The choice of shell fabric will determine the style of the entire necktie. The necktie style has striped, plain, polka dot, floral, paisley,checks, Etc. The fabric of the necktie Shell has the following long-standing materials: polyester, microfiber, silk, wool, cotton, and linen. They may be singly or mixed. Shell is also known as Envelope.

2. Blade

The blade is the central part of the necktie, taking up 2/3 of the tie.

When people wear a necktie, the Blade can best bring out your perfect temperament.

3. Neck

The neck is the middle part of the necktie. When people wear a necktie, it is the part of the necktie that touches the person's neck.

4. Tail

The tail is the narrow end of the necktie that hangs behind the Blade through the Label when knotted. It is usually half the length of the Blade.

5. Interlining

The interlining is wrapped by the Shell, and thus wholly hidden. The inner lining helps shape and maintain the tie's shape, adds fullness and drape to the necktie, and also prevents the necktie from wrinkling when worn.

A commonly used material for interlining is polyester because of its lower production cost. When making high-end neckties, such as yarn-dyed silk, interwoven silk, printed silk, cotton, linen, wool, etc. Buyers will choose interlinings of wool or wool and polyester blended materials to improve the overall quality of the product.

6. Keep Loop

The self-loop, or 'keeper loop,' is the loop that holds the necktie tail. On most neckties, buyers usually require us to make the Keeper loop with the same fabric as Shell. In a few cases, buyers will add the brand label (It is the Label Now) when designing Keeper Loop to make your tie design unique; of course, this will incur extra fees (Because of the necktie fabric and Keep loop fabric need to be woven alone). In rare cases, buyers will ask us to add both (keep loop and Label).

7. Label

Label and keeper loop have the same function. The existence of a Label or Keeper loop can make the necktie fully functional. The cost for buyers to use Label is higher than the Keeper loop, but it can make your necktie Stand out.

8. Tipping

Tipping is the fabric sewn onto the backside of the tip and Tail of a necktie. It completely hides the interlining at both ends of the tie, making the tie design more beautiful.

'Decorative-tipping' uses a fabric different from the shell of the necktie, and the fabrics available on the market are usually polyester. "Decorative tipping" is generally used for cheap ties.

'Self-tipping' uses the same fabric as the Shell and completes the cutting together with the Blade, Tail, and neck.

'Logo-tipping' generally uses the same fabric material as the shell but not the same design; its fabric weaving and cutting are separate from the shell. 'Label-tipping' will add more hours to workers.

9. Care & origin tag

The care & origin label contains detailed information about the tie. It may include country of origin, materials used, and special care instructions.

Details of the Necktie

1. Seam

A necktie usually has two seams. It is the trace after the worker sews the blade, neck, and tail of the necktie together. It is generally at a 45-degree angle and looks more beautiful.

2. Rolled edge

The edge of the necktie is rolled up after being pressed by the machine, maintaining a natural curvature. The rolled edge ensures a fullness at the border as opposed to a flat crease.

3. Bar Tack

Near each tip of the necktie, we can find a short horizontal stitch. This stitch is called the bar tack. It is manually hand-stitched over once or several times to secure the closure, ensuring the necktie doesn't come undone.

There are two types of bar tack (Usual Bar Tack and Special Bar Tack); Special bar tack sewed uses better thread, and the sewing method is more complicated and time-consuming.

4. Margin/Hem

The 'Margin' is the distance from the blade's edge to the tipping. The 'Hem' is the finishing stitch that connects the Shell to the tipping. Together the margin and hem allow for a soft rounded edge and keep the tipping hidden when seen from the front.

5. Slip stitch

Slip stitch is made with a single long thread and runs the entire necktie length; this sewn the two overlapping sides together and helps a necktie regain its shape after wear. The slip stitch was sewn loosely to prevent breakage from repeated knotting.

Now that you know all about the structure of a necktie, if you want to be an expert in necktie procurement, you need to learn more. Please Click to learn: How a Tie Factory Makes Handmade Jacquard Neckties in Batches.

Post time: Jun-29-2022