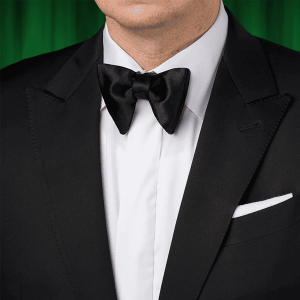

YiLi Rainbow Self-Tie Bow Tie – Bulk Order Ready

Product Video

Bowtie Size Customization

Bow tie dimensions are typically determined by both length and width. The length, measuring from the top to the bottom of the tie, usually falls within the range of 12-14 inches. Meanwhile, the width, extending from left to right, typically spans 2-3 inches.

It's crucial to select a tie size that complements the wearer's physique. Taller individuals may opt for a tie that is both longer and wider, while shorter individuals may find a smaller bow tie in both length and width more fitting.

Furthermore, the choice of tie size can be influenced by the occasion. Formal events may call for a larger tie, both in terms of length and width, while casual occasions might be better suited for a tie with smaller dimensions.

This way, the size of the tie not only caters to the wearer's proportions but also aligns with the specific demands of the occasion, ensuring a stylish and well-suited appearance.

| Classic Self-tied Bowtie | ||||

|---|---|---|---|---|

| Age Group | Bow | Neck | Total Length | Vertical End Height |

| Children | 10-12 inches | 1.5-2 inches | ||

| Youth | 12-13 inches | 2-2.5 inches | ||

| Adults | 12-14 inches | 2-3 inches | ||

| Classic Pre-tied Bowtie | ||||

|---|---|---|---|---|

| Age Group | Bow | Neck | Total Length | Vertical End Height |

| Children | 10-12 inches | 1.5-2 inches | ||

| Youth | 12-13 inches | 2-2.5 inches | ||

| Adults | 12-14 inches | 2-3 inches | ||

Bowtie Wearing Styles

Self-Tied

Self-tie bow ties offer a classic and more traditional look. They are commonly worn in formal or semi-formal settings, such as weddings, black-tie events, or upscale parties. Tying a bow tie can be a skill to master, but many people appreciate the sense of craftsmanship and personalization that comes with wearing a self-tie bow tie.

Pre-tied

Pre-tied bowties are convenient for those who prefer a polished and consistent look without the need for manual tying. While they are popular among individuals who may not be comfortable tying a bow tie, some formal occasions and fashion enthusiasts favor the classic and personalized touch of a self-tie bow tie.

Bowtie Color Customization

Our exclusive color customization service not only caters to the unique preferences of our customers but also goes beyond to assist them in designing eye-catching color combinations for their bow ties. By leveraging our expertise, clients can create bespoke bow ties that not only align with their individual color preferences and style choices but also showcase captivating and visually appealing color harmonies. Whether through Pantone color codes, images, or physical samples provided by the customer, our meticulous approach ensures seamless integration of personalized design and aesthetics, resulting in bow ties that truly stand out.

Bowtie Shape Customization

Butterfly Bowtie

Narrow Batwing Bowtie

Diamond Bowtie

Semi bowtie

Bowtie Excipient Customization

Bowtie Wash Label

The contents of the washing Lable usually include information such as material, washing method, and place of origin.

Bowtie Buckle Strap

We can customize the color, material, and weaving process of Bowtie Buckle Strap.

Bowtie Metal Buckle

Common materials for bow tie buttons include metal and plastic. We also support color customization.

Bowtie Packaging

Novel packaging is the prerequisite for bow ties to stand out. Good packaging design is a reflection of the strength of your brand.

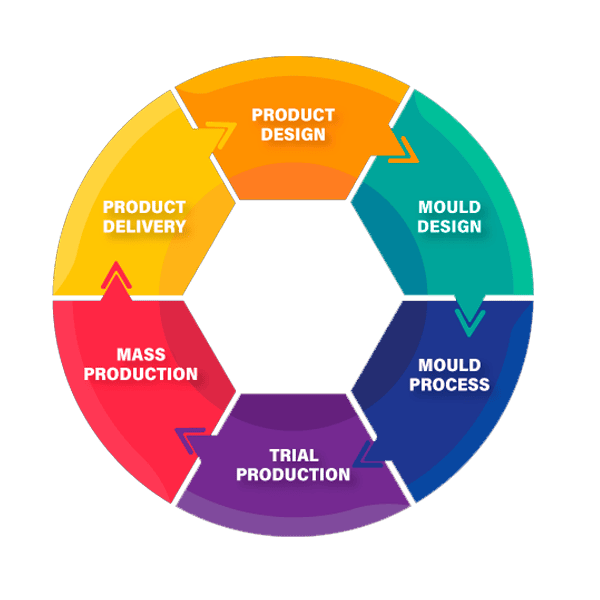

Efficient Production Capacity

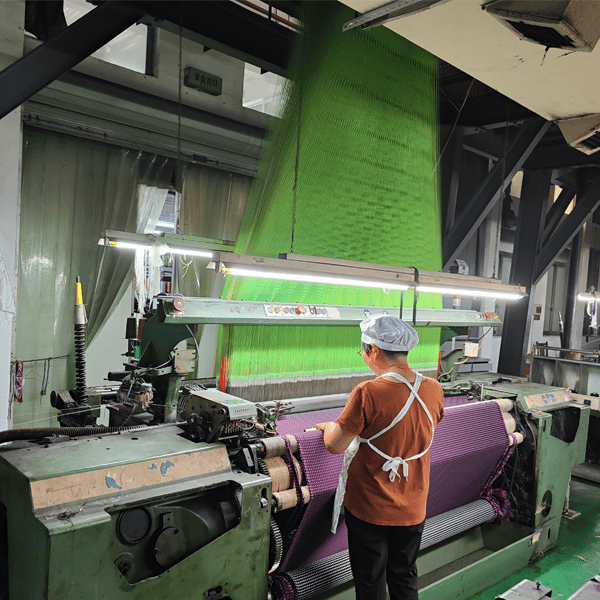

Fabric Production Workshop

Within the heart of our Fabric Production Workshop, YILI Company takes pride in its formidable workforce, surpassing 100 dedicated employees. Complementing this strong human element is our cutting-edge infrastructure, equipped with 56 state-of-the-art computerized weaving machines. This harmonious blend of skilled professionals and advanced technology empowers us to consistently achieve an impressive daily fabric output that surpasses 1,000 meters.

As leaders in the field, we continuously strive to set new benchmarks, and our commitment to delivering high-quality fabrics remains unwavering. It is this commitment that positions YILI Company at the forefront of the textile industry, where efficiency and excellence converge to redefine the standards of fabric production.

Neckie Production Workshop

In the vibrant setting of our Necktie Production Workshop, a dedicated and skilled team of over 50 production workers meticulously crafts our exquisite ties. This team operates within a well-organized workshop that boasts two highly efficient tie production lines, contributing synergistically to our remarkable daily processing capacity of 5,000 ties.

We prioritize quality throughout our tie-making process, we implement a thorough three-step inspection to ensure the production of ties of the highest standard. The first step involves a meticulous examination of the necktie fabric piece, ensuring that each piece meets our stringent quality criteria. Following this, a comprehensive inspection is carried out on the tipping of the ties, guaranteeing precision and excellence in the finishing details. The final stage involves a rigorous inspection of the completed neckties, where each tie undergoes a meticulous examination to ensure it meets our uncompromising quality standards.

Quality Assurance

Our Advantage

ONE-STOP PRODUCTION

YILI is a source-to-end factory, capable of handling everything from fabric production to tie manufacturing.

Certified Sustainable Practices

Upholding certifications such as BSCI, ISO9001, WCA, and SMATE, and sourcing OEKO-TEX-certified yarn suppliers.

Self-Supporting Fabric

Our self-reliance in fabric production offers unparalleled flexibility, agility, and stringent quality oversight during sample production.

Versatile Team

Our team including dedicated business, design, production, and e-commerce teams, enables efficient cross-functional collaboration and exceptional customer service.